Date

May 31, 2022

TRIA designed kitchen and community meeting space.

DPS Group, privately-owned, global engineering, procurement, construction management and validation (EPCMV) firm serving high-tech process industries, and design affiliate TRIA, a partner-led architecture firm with a focus on science and technology organizations bringing new discoveries to the market, congratulate CRISPR Therapeutics for being selected as the 2022 Facility of the Year Awards (FOYA) category winner for innovation by the International Society of Pharmaceutical Engineering (ISPE) for the CRISPR Therapeutics manufacturing facility in Framingham, Massachusetts. ISPE’s Facility of the Year Awards is an annual program that recognizes state-of-the-art projects utilizing new, innovative technologies to improve the quality of products, reduce the cost of producing high-quality medicines, and demonstrate advances in project delivery.

“Driven by our unwavering commitment to address patient needs, we are proud to be recognized by ISPE as 2022 Facility of the Year in Innovation for our state-of-the-art manufacturing facility in Framingham, Massachusetts that has been innovatively designed with flexibility and scale in mind,” said Stephen Kennedy, Head of Tech Operations at CRISPR Therapeutics.

Winners in the innovation category exemplify the novel application of process manufacturing techniques, innovative design concepts, new technologies and unique solutions that exemplify the next generation of agile, flexible, efficient and effective new and existing pharmaceutical and biotechnology facilities. This includes implementation of commercially available and custom developed equipment which yielded superior results, improved competitive position, and/or demonstrated imaginative collaboration with vendors/suppliers/manufacturers.

CRISPR Therapeutics is harnessing the CRISPR/ Cas9 gene-editing platform to develop gene-based medicines for patients with serious diseases. The project was awarded a FOYA award for Innovation based on the innovative design of the facility, which provides an end-to-end solution for production and fills operations.

“We are very thankful for all our partners in this project. DPS did a great job with engineering and the design of the project and keeping the team integrated and coordinated even throughout the COVID-19 pandemic,” added Brad Ebel, Framingham Facility Site Leader at CRISPR Therapeutics. “We extend our congratulations to the full team who worked on this rewarding project.”

The ISPE FOYA judging committee was impressed by many facets of the submission, which included:

- Digital systems and automation at all levels of the operation allow continuous monitoring and efficient product production and release;

- A flexible utilization model allows for concurrent production of multiple products at different stages of development;

- Independent and/or redundant utilities supplying individual clean rooms allow for continuous production without the need for a facility-wide maintenance shutdown, and

- Facility Vaporized Hydrogen Peroxide (FVHP) system to support rapid product changeover and reduction in the use of environmentally harmful chemicals.

The CRISPR Therapeutics manufacturing facility was designed thoughtfully and innovatively, and the ability of the facility to catalyze the promise of the technology impressed the judges. The facility is unique in utilizing a compact design with multiple independent production suites, each capable of producing a different product at a different stage of development while maintaining strict product segregation. The judges were particularly impressed with the use of a fully integrated digital stack that enables a small on-site warehouse to be continuously supplied from external sources yet still maintain uninterrupted production and testing operations. While the facility design was grounded in fundamental good engineering practices, there was intentionality in the flexibility of the facility that the committee found very innovative.

Following a series of user group meetings and executive workshops DPS was able to glean CRISPR’s operational needs which were then used to develop a best-in-class cGMP design for cell therapy and AAV production. The DPS team worked collaboratively with CRISPR Therapeutics on numerous process design layouts and scenarios to create spaces that will be flexible for years to come. DPS Group’s in-house experts were able to advise CRISPR on industry best practices across all engineering disciplines throughout schematic design, design development, and construction administration. Working with the CRISPR team as business needs evolved was essential to the project’s overall success.

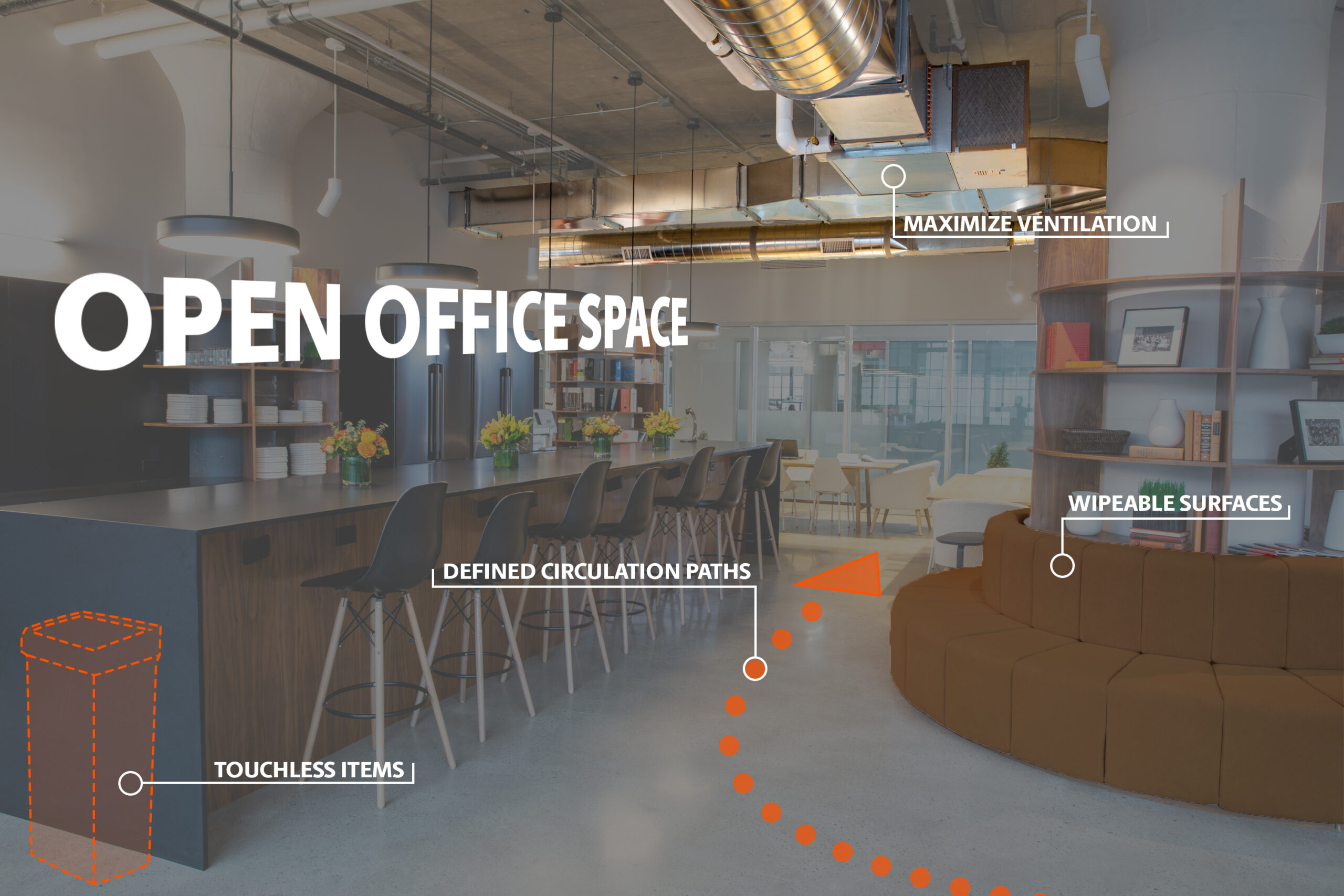

Through group visioning sessions, executive workshops, and focus groups, TRIA identified the spatial and aesthetic needs for the quality labs and office space. TRIA’s lab and workplace design expertise and information collected during the visioning, programming, and planning process enabled the creation of an efficient and unique design. The open plan office and amenity spaces promote interaction and collaboration. The design embraces the abundant natural light and the exposed steel structure of the building. Glass walls are incorporated throughout to provide transparency, natural light and a connection between the office and manufacturing space.

Supply partners and key participants include:

- Manufacturer/Owner: CRISPR Therapeutics

- Architect: TRIA Design

- Engineer: DPS Group Inc.

- Owners Representative (OPM): Leggat McCall Properties LLC

- Construction Manager/General Contractor: Commodore Builders LLC

- Structural Engineer: Pare Corp.

Serving high-tech industries around the world, DPS Group delivers full-service engineering across a range of disciplines, including project management, procurement, design, construction management, health and safety management, commissioning, qualification, and validation (CQV), and facility start-up.